How Kusshal Loggistics Manages On-Time Deliveries with Smart Full Truck Load (FTL) Services

Blogs

How Kusshal Loggistics Manages On-Time Deliveries with Smart Full Truck Load (FTL) Services

Kusshal Loggistics helps manufacturers, distributors and retailers move full truckload shipments across India with a clear focus on speed, route control and customer visibility. Clients do not want surprises during shipment. They want delivery information that is accurate and shared before problems begin.

Kusshal Loggistics manages this using GPS-equipped trucks along with a trained route-monitoring team and real-time delivery updates built into its transport management system.

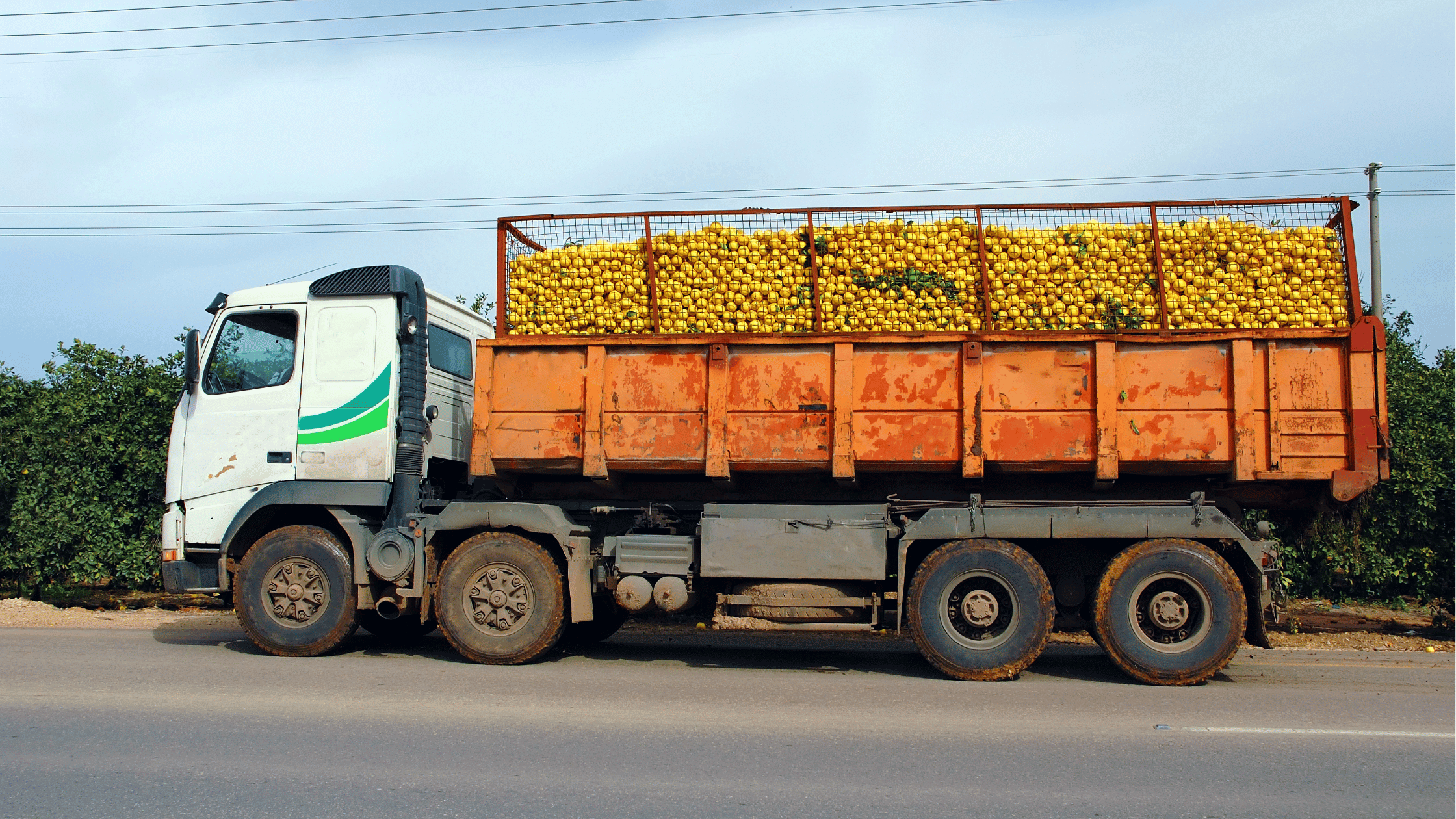

Full truckload movement is often used when clients ship large volumes of raw materials, packaged goods or retail-ready inventory from factories to warehouses or from distribution hubs to retailers. Even small route delays can create major inventory gaps at destination.

The company manages over 10,000 SKUs across India using real-time GPS and route control:

Kusshal Loggistics operates a fleet of GPS-enabled trucks across major Indian lanes such as Mumbai to Pune, Ahmedabad to Bengaluru, Surat to Indore and many more. The trucks carry goods from different sectors including FMCG, electronics, spare parts, fashion, construction materials and medical supplies.

Each shipment is tracked using GPS hardware that streams location data directly into Kusshal Loggistics’ transport management system (TMS). This tracking does not just show where the vehicle is. It also shows the speed of movement, current route taken, fuel level and estimated arrival time.

Clients access this data through the same platform used by Kusshal’s internal teams. That removes the need to send repeated follow-ups to know where a truck is or when it will reach the gate.

Route performance is reviewed daily across each delivery lane:

FTL operations depend on known routes and tested schedules. But in India, routes often change due to toll blocks, construction activity, political events or monsoon-related closures.

Kusshal Loggistics monitors its daily vehicle movements across every city corridor and adjusts route plans based on actual travel performance.

The operations team keeps a rolling record of travel times, loading delays, rest stops and client unloading preferences. That data is used to build realistic timelines instead of guesswork-based promises.

Drivers are supported with direct control and issue tracking from the control room:

Kusshal Loggistics assigns each active FTL shipment to the control room supervisor. This person is responsible for watching the GPS, co-ordinating with the driver and guiding the driver during issues.

If a truck stops for too long, takes a wrong turn or misses a delivery window, the supervisor acts immediately. The driver is called. The route is adjusted. The client is informed. The issue is not passed on to a third-party dispatcher.

This model works well because Kusshal Loggistics owns its core fleet and works with long-term driver teams. That gives them direct control and consistency in how issues are handled.

Clients get daily delivery reports that track accuracy and delay margins:

Kusshal Loggistics does not wait for clients to ask where the truck is. A delivery report is shared daily for all active shipments. This report includes the current location, last checkpoint crossed, delivery slot and expected buffer. Kusshal Loggistics understands that shipment visibility is not a bonus. It is a basic need.

Buffer planning is built into all full truckload routes:

It is not enough to plan for fast delivery. A good plan also accounts for what may go wrong. Kusshal Loggistics adds timing buffers to all long-distance FTL shipments based on live route data.

These buffers are not generic. They are based on lane-specific travel patterns, recent delay data and seasonal risk. This buffer is included in the delivery ETA shared with clients. So even when problems happen, the shipment still arrives inside the confirmed slot.

Clients using Kusshal Loggistics for FTL services benefit from the following delivery features: